The petrochemical engineering industry has critical applications, and it’s very difficult to select the correct wire mesh to maintain the integrity, efficiency, and safety of various processes and equipment. Stainless steel wire mesh is used in filtration, separation, protection, and support systems within petrochemical plants. Here we will study the key points and the best wire mesh options for petrochemical engineering applications.

Some Major key points to consider when selecting wire mesh for petrochemical engineering:

Material: The Compatibility of martial arts is important in the selection of wire mesh. Always using corrosion-resistant and high-temperature resistant wire mesh is advisable for petrochemical plants. Stainless steel alloys, such as 304, 316L, or 904L, are most usable or advisable due to their excellent performance in corrosion and high-temperature environments.

Mesh Size and Aperture: The mesh size and aperture play a vital role in selecting the perfect wire mesh for the application. Fine mesh is usable to filter the fine impurities where big sizes are used for supporting layers to the fine filter system or mesh, which is known as coarse filtration. 40 mesh, 30 mesh, 60 mesh, 80 mesh, 100 mesh, etc. are examples of the filtration of polymers in the extrusion process.

Strength and Durability: Most petrochemical processes involve high pressures, mechanical stresses, and abrasive conditions. It’s very important to select a wire mesh for a process in petrochemical engineering with sufficient strength and durability to withstand these factors and maintain its structural integrity over time.

Regulatory Compliance: Petrochemical plants follow industry standards and regulations, so wire mesh selection should comply with relevant codes like filtration efficiency, fire resistance, chemical resistance, corrosion resistance, etc.

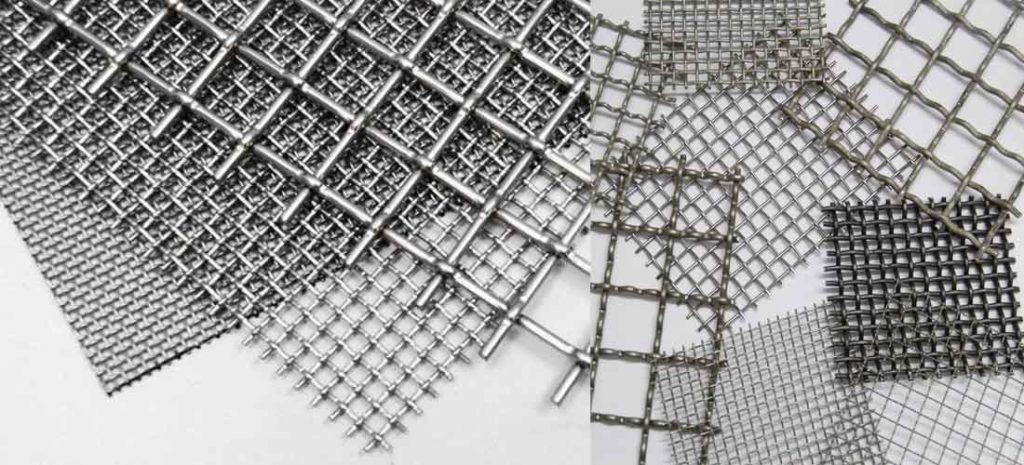

Petrochemical industries most commonly use Wire Mesh Types:

Plain Dutch Weave Wire Mesh: As the name suggests, it comes from Europe and is popular for its high strength, stability, and excellent filtration capabilities. They consist of tightly woven wires, with smaller openings in the warp direction and larger openings in the weft direction. This type of mesh is often used in critical filtration applications where fine particle retention is required.

Reverse Twill Dutch Weave: This is a combination of twill weave and Dutch weave wire mesh. This type of wire mesh is used where we have extreme levels of pressure and temperature. The weft wire is thicker than the wrap wire. With this mechanical property, the performance of wire mesh has been increasing. The most common applications are food, polymers, plastics, etc.

Plain Wave Wire Mesh: It is also known as square wire mesh. This type of wire mesh is suitable for supporting layers as well as where processes do not require much durability with fine filtration stability. In this wire mesh, both weft and wrap are the same size.

Plain Twilled Weave Wire Mesh: Twilled weave mesh is a good example of how to maintain the strength and filtration efficiency of wire mesh. Due to the diagonal pattern, it has a higher flow rate compared to plain weave meshes. Twilled-weave mesh is advisable for petrochemical applications where moderate filtration is required combined with mechanical strength.

Conclusion: Selecting the correct wire mesh for petrochemical engineering applications involves several factors such as material compatibility, mesh and aperture size, wire mesh strength, flow rates, and regulatory compliance. The commonly used wire mesh types in this industry are Dutch weave, twilled weave, Plain weave, Reverse twill Dutch weave, etc. All these factors will help us select an appropriate wire mesh to ensure the optimal performance and longevity of wire mesh installations in petrochemical plants. When it comes to reliable wire mesh solutions for the petrochemical industry, SRK Metals is a trusted company that offers high-quality wire mesh products. With their expertise and commitment to excellence, we provide reliable and durable wire mesh solutions that meet the stringent requirements of petrochemical engineering applications. Our wide range of wire mesh products is designed to withstand the harsh conditions and corrosive environments typically encountered in petrochemical plants.

I like the valuable info you provide in your articles. I抣l bookmark your weblog and check again here regularly. I’m quite sure I will learn many new stuff right here! Best of luck for the next!