Wire cloth, a versatile material in the realm of industrial applications, stands as a testament to its durability, adaptability, and multifunctionality. With its myriad forms and variations, from heavy-duty rolls to finely woven meshes, wire cloth embodies a spectrum of uses and materials, making it an indispensable element across diverse industries.

What Constitutes Wire Cloth?

Imagine a symphony of metallic threads intricately woven together to create the versatile marvel we know as wire cloth. Crafted from a fusion of stainless steel, carbon steel, or galvanized steel, this amalgam forms a resilient, enduring, and rust-defying fabric, a versatile solution catering to an expansive spectrum of uses.

Manufacturing Process and Quality Assurance

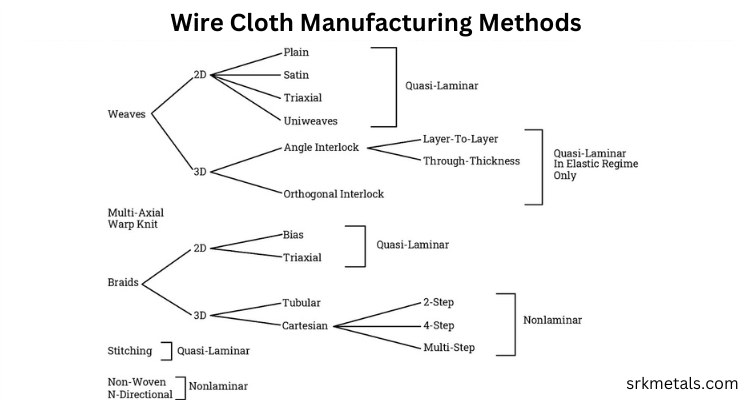

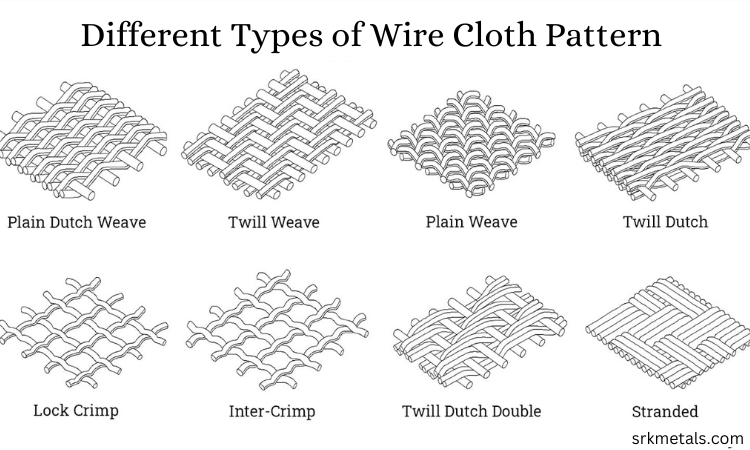

The manufacturing process of wire cloth involves intricate weaving techniques and meticulous attention to detail to ensure quality and durability. Welded wire mesh and woven wire cloth, the primary manufacturing methods, contribute to the diversity and adaptability of wire cloth products available in the market.

Different Types of Wire Cloth:

Each type of wire cloth serves specific industry needs due to its distinctive material properties, catering to a wide range of applications and requirements. Hence, there are some of the prime picks for projects; explore wire cloth types:

Stainless steel cloth: Among wire cloth options, stainless steel shines with its unbeatable versatility and lasting durability. Its resistance to corrosion and impressive strength make it an ideal choice for various applications, particularly in filtration and fencing.

Nickel Wire Cloth: Similar to stainless steel, nickel wire cloth offers enhanced chemical resistance. Its properties make it particularly well-suited for environments that demand high durability and resilience.

Epoxy-Coated Wire Cloth: The epoxy-coated wire cloth boasts corrosion resistance due to an added epoxy layer. It finds extensive use in environments exposed to corrosive elements, offering protection and longevity.

Copper and Brass Wire Cloth: The copper and brass wire cloth not only presents a unique aesthetic appeal but also offers excellent conductivity. They serve well in decorative applications and electrical purposes due to their properties.

Aluminum Screen Wire Cloth: Insect screening and ventilation systems rely on the durability of aluminum screen wire cloth, which is both lightweight and corrosion-resistant.

Variants of Wire Cloth:

There are various types of ranges available in wire cloth. One can avail it as per the project requirements and also customize it if needed.

Heavy Duty Wire Cloth: Engineered for rigorous usage, this variant is capable of withstanding substantial pressure and is often employed in demanding industrial environments. Woven with intricate patterns, this type achieves remarkable strength and flexibility, making it a versatile choice for many purposes.

Wire Cloth Roll: Provided in roll form, this facilitates convenience in handling, cutting, and customization, catering to specific project requirements.

Wire Cloth Mesh: Available in various mesh sizes, this type of cloth accommodates different filtration and sieving needs.

What is Wire Cloth Used For?

Wire cloth finds its application across a spectrum of industries, serving diverse purposes:

Filtration and Separation: Wire mesh is extensively used in filtration systems across industries such as oil and gas, chemical processing, and water treatment. It efficiently separates solids from liquids or gases, allowing for precise filtration due to its varying mesh sizes and materials.

Security and Protection: In construction, wire mesh serves as reinforcement in concrete structures, providing strength and durability. Moreover, this versatile material finds its application in fencing and fortifications, serving as a safeguard in diverse residential, commercial, and industrial landscapes.

Screening and Sifting: Industries like mining, agriculture, and food processing utilize wire mesh for screening and sifting applications. It helps in sorting materials by size, separating particles, and ensuring product quality by removing impurities.

Decorative and Architectural Purposes: Wire mesh is employed in architectural designs and interior décor for its aesthetic appeal. It’s used in facades, ceilings, walls, and artistic installations due to its ability to create visually appealing patterns and textures.

Industrial Sieving and Sieve Analysis: Laboratories and manufacturing industries utilize wire mesh for sieving and sieve analysis to determine particle size distribution in materials. This is crucial for quality control and research across various sectors, like pharmaceuticals, food, and construction materials.

What is the difference between chicken wire and wire cloth?

While wire cloth and chicken wire may appear similar due to their wire-based construction, several distinctions set them apart. Chicken wire typically comprises larger, hexagonal-shaped openings and is crafted from lighter gauge wires, primarily serving applications of chicken wire such as fencing to make enclosures for chickens in poultry farms and for other various small animals.

Wire cloth, on the other hand, offers a diverse range of mesh sizes and wire diameters, tailored for precision applications such as filtration, sieving, and industrial uses.

What material is wire fabric?

A wide variety of options are available here as a wire fabric in manufacturing, such as material compositions such as:

Stainless Steel: Renowned for its corrosion resistance and durability, stainless steel wire cloth. Furthermore, it is often preferred for the applications demanding hygiene, such as food processing and pharmaceuticals.

Carbon Steel: Carbon steel wire cloth, known for its strength and affordability, finds its primary use in industrial settings where durability and cost-effectiveness are crucial.

What is Universal Wire Cloth?

This versatile variant is suitable for a broad range of applications owing to its adaptability and durability.

What is a wire-cloth sieve?

Specifically designed for accurate particle separation and analysis, this variant plays a pivotal role in industries requiring precision.

Conclusion: Embracing the Versatility of Wire Cloth

In conclusion, wire cloth stands as a testament to human ingenuity and innovation in material engineering. Its wide range of applications, material variants, and manufacturing techniques make it a cornerstone in numerous industries worldwide. From heavy-duty filtration to precision sieving, wire cloth continues to serve as a fundamental component. It offers high-quality and custom solutions across various sectors.

As industries evolve and demand sophisticated solutions, Wire Cloth stands ready to adapt and cater to diverse needs. Also perpetuates its legacy as a vital element in the fabric of modern industrial applications.

Looking for reliable wire cloth solutions? SRK Metals offers high-quality, customizable options that strengthen your projects. With a wide range of metals, sizes, patterns, and expert guidance, we ensure satisfaction and project success. Contact us today for top-notch wire cloth in Dubai, Sharjah, Abu Dhabi, Fujairah, and across the UAE. Strengthen your projects with durability and aesthetic appeal by choosing SRK Metal.